Introduction to ball mill lining

Introduction to ball mill lining

The ball mill lining is an important part of the ball mill, which protects the mill and pulverand grinthe material by lifting the grinding ball and minerals. In the long time of work, ball mill liner widespread wear problems, this paper will introduce the causes of several ball mill wear and countermeasures.

1. The material and heat treatment process of the lining plate are unreasonable

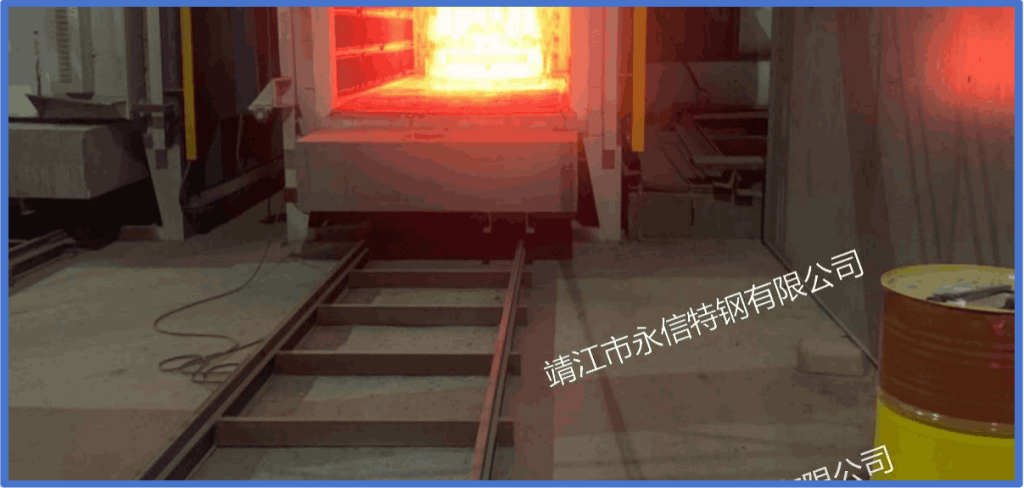

Heat treatment of the liner is an important way to reduce the wear of the ball mill liner. The material and heat treatment process of the liner directly determine the mechanical properties of the liner, and will also have an important impact on the wear of the liner. Therefore, according to the material of the lining plate, choose the appropriate heat treatment process.

However, in the actual work, the relevant staff lack the cognition of the material of the lining plate, in the process of heat treatment, the processing of the lining plate is insufficient, not only did not play the role of strengthening, but also reduce the strength of the lining plate, in the steel ball, material impact, there will be plastic deformation phenomenon will occur.

2. The ball mill is incorrect

Once the ball mill is in an abnormal operation state, it will also aggravate the wear of the ball mill liner. Generally speaking, the steel ball in the ball mill is mixed with the material, so when the steel ball hits the lining plate, the material will play a certain buffer role. When the ball mill is running at low load, the steel ball will directly impact the lining plate, resulting in serious wear of the lining plate, and even fracture.

Coping measures for wear of ball mill liner

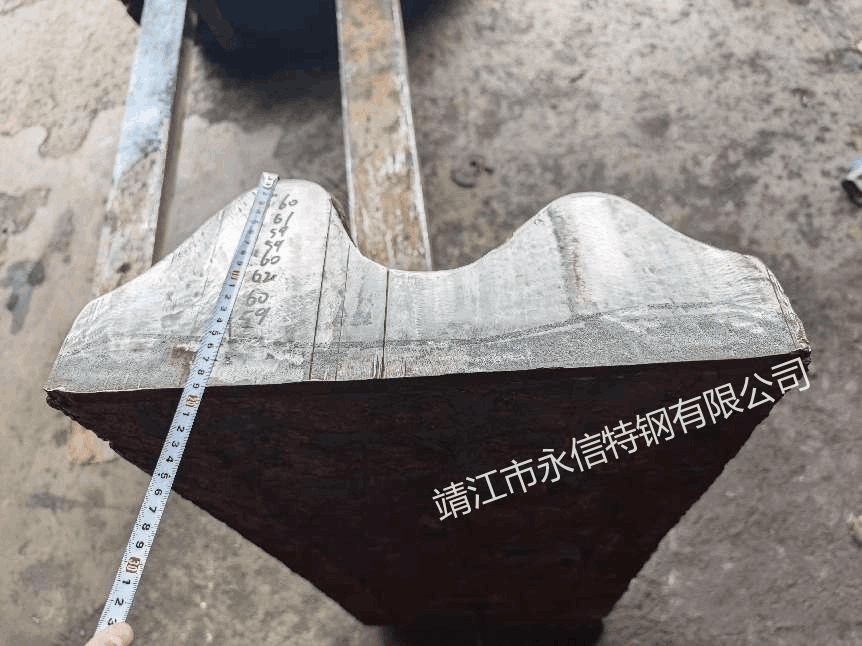

1, a reasonable selection of steel ball and lining board

Reasonable selection of steel ball and lining plate is an important way to reduce the wear of the lining plate, so the relevant staff need to consider the size, number, ball mill lining plate and steel ball hardness ratio, fundamentally reduce the loss of the lining plate during the operation of the ball mill. In addition, it is also necessary to control the material of the lining plate and the hardness of the steel ball, both aspects need to be in accordance with the regulations. Generally speaking, the hardness ratio of the ball mill liner and the steel ball should be controlled at about 1:0.8. At the same time, we should do a good job of the ball mill steel ball and the lining board, according to the material and hardness of the lining board, the reasonable choice of the lining board heat treatment process.

2, the use of a new material lining board

With the progress of technology, the new material of the liner also began to be applied in the ball mill, such as the composite liner composed of bimetallic metal, which preferably solves the contradiction between the toughness and hardness of the liner, and reduces the impact of the liner in the process of operation.

Compared with the ordinary liner, the heat resistance and strength of the composite liner have been greatly improved, especially in terms of service life, the composite liner is twice that of the traditional liner, which greatly improves the economic benefit of the enterprise. Can better improve the liner aging and liner wear and other problems.

3. Control the running state of the ball mill

Controlling the running state of the ball mill is also an important measure to deal with the wear of the lining plate, so to ensure the reasonable proportion of the ore powder and the steel ball in the ball mill. Generally speaking, the ore powder is about twice that of the steel ball. If this proportion is unbalanced, it is easy to cause the low load to run of the ball mill, resulting in the steel ball to directly impact the liner, causing the fracture of the liner. Therefore, when the ball mill runs with low load, it is necessary to adjust the intake of the ball mill in time, so as to improve the grinding coefficient of the ore.

The above introduces the reasons and countermeasures of several ball mill wear. In order to deal with the wear problem of ball mill liner in time, the staff needs to understand the causes of liner wear and be able to make corresponding solutions. If in the actual work, the ball mill liner wear problem is not well solved, it is suggested to consult the professional ball mill manufacturers.