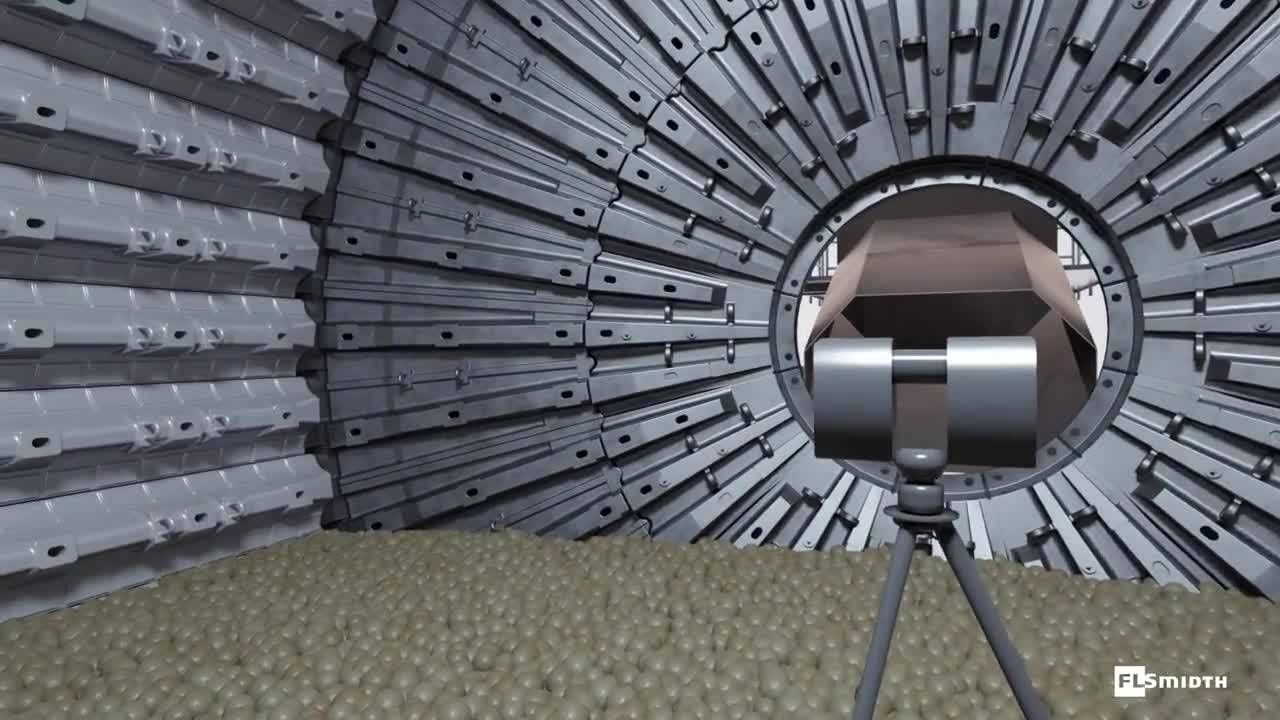

Φ3.3m*6.6m ball mill liners

Home > Products > Ball Mill Iining >

FQA

The Φ3.3m*6.6m ball mill liners are used inside ball mills to protect the cylinder, enhance its strength, and improve grinding efficiency while extending the mill’s lifespan. They are widely used in cement plants, mines, chemical plants, and other industries.

Product Features:

- High Wear Resistance: Made from highly wear-resistant materials, effectively resisting abrasion and extending the service life of the liners.

- Excellent Mechanical Properties: High strength and good toughness, capable of withstanding strong impacts inside the ball mill.

- Easy Installation and Maintenance: Reasonably designed for easy installation and replacement, reducing downtime and maintenance costs.

- Optimized Design: The shape and layout of the liners are optimized to enhance grinding efficiency and output.

- Eco-friendly Materials: Made from non-toxic, environmentally friendly materials, posing no harm to the environment.

Product Specifications:

- Diameter: 3.3 meters

- Length: 6.6 meters

- Material: High-chromium alloy, high manganese steel, or other wear-resistant materials

- Weight: Determined by specific material and design

- Applicable Models: Suitable for ball mills with a diameter of 3.3 meters and a length of 6.6 meters

Applications:

- Cement Industry: Used as internal liners for cement ball mills to protect the cylinder and improve grinding efficiency.

- Mining Industry: Suitable for crushing and grinding ores, widely used for iron ore, copper ore, gold ore, and more.

- Chemical Industry: Used for grinding chemical raw materials, enhancing the fineness and uniformity of the product.

Usage Instructions:

- Pre-installation Check: Before installation, check the cleanliness of the ball mill cylinder to ensure it is free of debris.

- Regular Maintenance: Regularly inspect the wear condition of the liners during use and promptly replace severely worn liners.

- Standard Operation: Operate strictly according to the ball mill’s operation procedures to avoid damage to the liners due to improper use.

Contact Information

For more information about the Φ3.3m*6.6m ball mill liners, please contact our sales team. We are committed to providing you with professional consultation and service.